The Ongoing Saga of 3D Printing in Healthcare

17 Oct, 2023

Healthtrip Team

Healthtrip Team3D Printing in Medicine – a realm where innovation and healthcare join forces to revolutionize the way we think about surgeries. Let's embark on a journey that explores the magic behind this cutting-edge technology and unravels the significance it holds for the future of medical procedures.

3D Printing in Medicine

A printer, not crafting documents or photos, but creating intricate medical marvels. That's the essence of 3D printing in medicine. We're talking about a revolutionary process that builds three-dimensional objects layer by layer, with applications ranging from customized implants to bio-printed organs. It's like bringing a surgeon's vision to life in ways we never dreamed possible.

Transform Your Beauty, Boost Your Confidence

Find the right cosmetic procedure for your needs.

We specialize in a wide range of cosmetic procedures

Now, you might be wondering, why all the buzz about revolutionary surgeries? Well, buckle up, because this is where things get truly exciting. 3D printing is reshaping the landscape of surgical procedures, offering tailor-made solutions for patients. Think of it as personalized medicine at its finest – where each implant, each surgical guide is crafted to fit an individual's unique anatomy.

The significance goes beyond just precision. It means quicker recovery times, improved outcomes, and a whole new frontier of possibilities in the world of healthcare. From custom bone implants to bio-printed organs, 3D printing is rewriting the rules, making surgeries not only more effective but also more humane.

Let's look at some stats

The global market for 3D printing in medicine is expected to reach $12.8 billion by 2028. (Source: Acumen Research and Consulting)

So, why settle for one-size-fits-all when you can have a surgery designed just for you? That's the game-changer we're exploring here – the marriage of technology and medicine, promising a future where healthcare is as unique as the individuals it serves. Get ready to dive into the details, because the future of medicine is here, and it's three-dimensional!

Most popular procedures in India

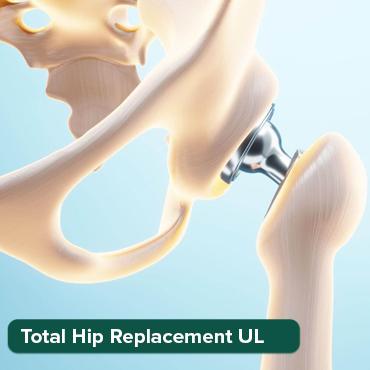

Total Hip Replacemen

Upto 80% off

90% Rated

Satisfactory

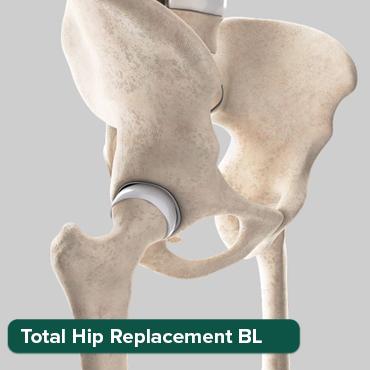

Total Hip Replacemen

Upto 80% off

90% Rated

Satisfactory

Total Hip Replacemen

Upto 80% off

90% Rated

Satisfactory

ASD Closure

Upto 80% off

90% Rated

Satisfactory

Liver Transplant Sur

Upto 80% off

90% Rated

Satisfactory

Foundations of 3D Printing in Medicine

A. Basics of 3D Printing Technology

1. Printing Materials

When we talk about 3D printing in medicine, it all starts with the materials. Imagine a palette of possibilities where biocompatible materials, metals, plastics, and even living cells come together to form the building blocks of medical innovation. These materials are carefully chosen to ensure not only the structural integrity of the printed objects but also their compatibility with the human body. From titanium implants to bio-inks used for organ printing, the choice of materials is at the core of what makes 3D printing in medicine so groundbreaking.

2. Printing Processes

Now, let's demystify the magic of how 3D printing actually happens. There are various processes at play, each with its unique strengths. From the meticulous layering of material in Fused Deposition Modeling (FDM) to the precision of Stereolithography (SLA), understanding these processes is like deciphering the language of a medical marvel. We'll delve into the nuts and bolts of these methods, exploring how they contribute to the creation of intricate and personalized medical solutions.

B. Historical Development

1. Milestones in 3D Printing for Medicine

3D printing coincide with giant leaps in medical possibilities. We'll walk you through the significant milestones, from the early experiments that sparked the idea of printing tissues to the present-day where entire functional organs are being created. Each milestone is a testament to human ingenuity and the relentless pursuit of improving healthcare through technology.

2. Evolution of Surgical Applications

The journey from the first 3D-printed prototypes to the operating room is a captivating one. We'll explore how 3D printing evolved from creating models for surgical planning to crafting patient-specific implants with unparalleled precision. The evolution is not just technological; it's a story of collaboration between engineers, surgeons, and medical researchers pushing the boundaries of what was once deemed impossible.

How Medical 3D Printing Works

1. Medical Imaging: The process begins with medical imaging, usually through technologies like CT scans, MRIs, or 3D ultrasound. These images provide detailed and accurate representations of a patient's anatomy, capturing the intricacies of bones, organs, and tissues.

2. Digital Model Creation: The medical images are then converted into digital 3D models using specialized software. These digital models serve as the blueprint for the 3D printing process, preserving the precise anatomical details captured in the imaging phase.

3. Segmentation: During this stage, the digital model is segmented, separating the different structures and elements within the anatomy. For example, in the case of reconstructive surgery, a specific organ or bone may be isolated for further customization.

4. Virtual Reconstruction: Surgeons and medical professionals can virtually manipulate and reconstruct the segmented digital model. This step allows them to plan surgeries with unparalleled precision, simulate complex procedures, and customize implants or prosthetics according to the patient's unique anatomy.

5. STL File Generation: The finalized digital model is then converted into a Standard Tessellation Language (STL) file. This file format represents the surface geometry of the 3D model using a series of interconnected triangles, making it compatible with 3D printing technology.

6. Choice of Printing Material: Depending on the intended application, the appropriate printing material is selected. Common materials include biocompatible plastics, metals like titanium, and bio-inks for printing living tissues. The choice of material is crucial to ensure compatibility with the human body and the functionality of the printed object.

7. Layer-by-Layer Printing Process: The actual 3D printing process begins. Most medical 3D printers use additive manufacturing techniques, such as Fused Deposition Modeling (FDM) or Stereolithography (SLA). Layer by layer, the chosen material is deposited or cured, gradually building the physical object based on the digital model.

8. Post-Processing: Once the 3D printing is complete, the object may undergo post-processing. This could involve the removal of support structures, polishing, or additional treatments to enhance the surface finish and functionality of the printed medical device or model.

9. Quality Control and Testing: Rigorous quality control measures are implemented to ensure the accuracy and safety of the 3D-printed medical object. This may involve imaging the printed object to compare it with the original digital model and conducting structural or functional tests.

Applications in Surgical Procedures

A. Patient-Specific Implants

1. Customized Bone Implants

In the realm of 3D printing, one size doesn't fit all, especially when it comes to reconstructing bones. We'll explore the marvel of creating patient-specific bone implants tailored to the unique anatomy of individuals. From jaw reconstruction to intricate cranial implants, 3D printing allows surgeons to design implants that seamlessly integrate with a patient's skeletal structure. This not only improves the fit but enhances the overall success and longevity of the implant, marking a significant leap in orthopedic and reconstructive surgery.

2. Organ Transplants and Bio-printing

Imagine a world where waiting for an organ transplant is a thing of the past. We'll delve into the groundbreaking field of bio-printing, where 3D printers construct living tissues and organs layer by layer. From heart valves to kidneys, we'll explore how this technology is pushing the boundaries of regenerative medicine. The promise of personalized organs, crafted from a patient's own cells, is not just futuristic—it's the next frontier in organ transplantation.

B. Surgical Guides and Models

1. Preoperative Planning

Precision is paramount in surgery, and 3D printing is transforming preoperative planning. We'll uncover how surgeons use 3D-printed models of a patient's anatomy to strategize and visualize complex procedures. This hands-on approach allows for a deeper understanding of the surgical landscape, enabling surgeons to anticipate challenges and optimize their approach. From intricate neurosurgery to delicate cardiovascular procedures, 3D-printed preoperative guides are revolutionizing the way surgeries are planned.

2. Training Simulations for Surgeons

Learning surgery is a delicate art, and 3D printing is bringing a new dimension to surgical training. We'll explore how surgeons-in-training hone their skills through realistic simulations using 3D-printed models. These models replicate the feel and complexity of human anatomy, providing a risk-free environment for surgeons to practice and refine their techniques. It's not just about learning to cut—it's about mastering the art of precision in a safe and controlled setting.

C. Prosthetics and Orthopedics

1. Advancements in Prosthetic Limbs

The world of prosthetics is undergoing a revolutionary transformation. We'll unveil how 3D printing is allowing for the creation of custom-fitted prosthetic limbs that not only restore functionality but also consider the wearer's comfort and aesthetics. From intricate hand prosthetics to advanced lower limb solutions, 3D printing is empowering amputees with prosthetics that feel like a natural extension of themselves.

2. Tailored Orthopedic Devices

Orthopedic solutions are no longer off-the-shelf. We'll explore how 3D printing is customizing orthopedic devices, from braces to joint implants, to match the unique needs of each patient. This personalization not only enhances comfort but also improves the overall effectiveness of orthopedic interventions. It's a paradigm shift in orthopedic care that puts the patient at the center of the treatment plan.

Benefits of 3D Printing in Medicine

- Enhanced Precision

- Tailored to Perfection: 3D printing allows for the creation of patient-specific implants and surgical guides, ensuring an unparalleled level of precision in medical procedures.

- Minimizing Margin of Error: Surgeons can navigate complex anatomical structures with greater accuracy, reducing the risk of errors during surgery.

- Reduced Surgery Time

- Streamlined Procedures: Customized 3D-printed tools and implants facilitate smoother surgeries, often reducing the overall time spent in the operating room.

- Efficient Preoperative Planning: Surgeons can plan and simulate procedures in advance, optimizing the surgical workflow and minimizing unnecessary delays.

- Improved Patient Outcomes

- Personalized Healthcare: The customization offered by 3D printing leads to improved patient outcomes as treatments are tailored to individual anatomies and conditions.

- Faster Recovery: Patients often experience quicker recovery times, thanks to the precise nature of 3D-printed interventions, minimizing trauma and promoting healing.

Risks and Challenges

- Regulatory Considerations

- Compliance Challenges: The rapidly evolving nature of 3D printing technology poses challenges for regulatory bodies in establishing and updating standards for medical applications.

- Quality Assurance: Ensuring the safety and efficacy of 3D-printed medical devices requires robust quality control measures to meet regulatory requirements.

- Ethical and Legal Implications

- Patient Privacy: The use of patient-specific data for creating 3D-printed models raises concerns about privacy and the secure handling of sensitive medical information.

- Liability Issues: As 3D printing becomes more integral to medical procedures, questions arise about liability in the event of malfunctions or unforeseen complications related to 3D-printed devices.

Future Trends and Developments

A. Ongoing Research and Innovations

Looking forward, ongoing research fuels the evolution of 3D printing in medicine. Innovations in printing materials, bio-printing, and even the prospect of 4D printing point towards a future where medical applications of 3D printing become even more advanced.

The synergy between technology and medicine is intensifying. Collaborations between engineers and healthcare professionals are yielding solutions that seamlessly integrate 3D printing into the fabric of modern medicine. From AI-assisted surgical planning to real-time adjustments, the collaborative efforts promise a future where technology enhances medical practice.

The potential for 3D printing to shape the landscape of medical tourism is on the horizon. As technology evolves, medical tourism destinations can leverage 3D printing to offer cutting-edge, personalized healthcare services, creating a unique appeal for international patients.

In summary, the exploration of 3D printing in medicine has showcased its precision in patient-specific solutions, transformative bio-printing, and personalized preoperative planning, leading to enhanced outcomes.

As we conclude, the future of 3D printing in medicine holds promise for more personalized, efficient, and accessible medical solutions. It's not just about technology; it's about reshaping the essence of healthcare delivery.

Wellness Treatments

Give yourself the time to relax

Lowest Prices Guaranteed!

Lowest Prices Guaranteed!